The RTAS series is an integrated multiple deposition sources machine to general graphite, jet black, blue, copper and bronze colors on metal parts, stainless steel objects. Particularly used for high end class luxury parts.

Standard Application

Jewelry, watch straps and bodies, Stainless steel sports, Writing instruments

Consumer electronics: Mobile Phone, Laptop, Camera, Drones

- Home Electronics,

- In-car Electronics;

- stainless steel flatware

- Medical Instrument and Implants

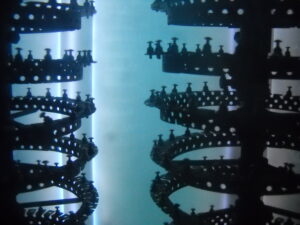

The RTAS machines equipped with circular arc and cylinder sputtering deposition sources. Multiple combinations of DC sputtering, MF sputtering, arc evaporation and Ion source etc. All are available in one single machine, for a high flexibility in configurations to satisfy various applications. Especially for small components aesthetic coatings: jet black, copper, brass and chrome colors.

What is MF Sputtering?

Compared with DC and RF sputtering, Mid-Frequency sputtering has become a main thin film sputtering technique for mass production of coating, particularly for the film deposition of dielectric and non-conductive film coatings on surfaces such as optical coatings, solar panels, multiple layers, composite material film etc.

It is replacing RF sputtering due to it operated with kHz rather than MHz for a much faster deposition rate and also can avoid the Target poisoning during compound thin film deposition like DC.

MF sputtering targets always existed with two-sets. Two cathodes are used with an AC current switched back and forth between them which cleans the target surface with each reversal to reduce the charge build up on dielectrics that leads to arcing which can spew droplets into the plasma and prevent uniform thin film growth— which is what we called Target Poisoning.

| No. | Name |

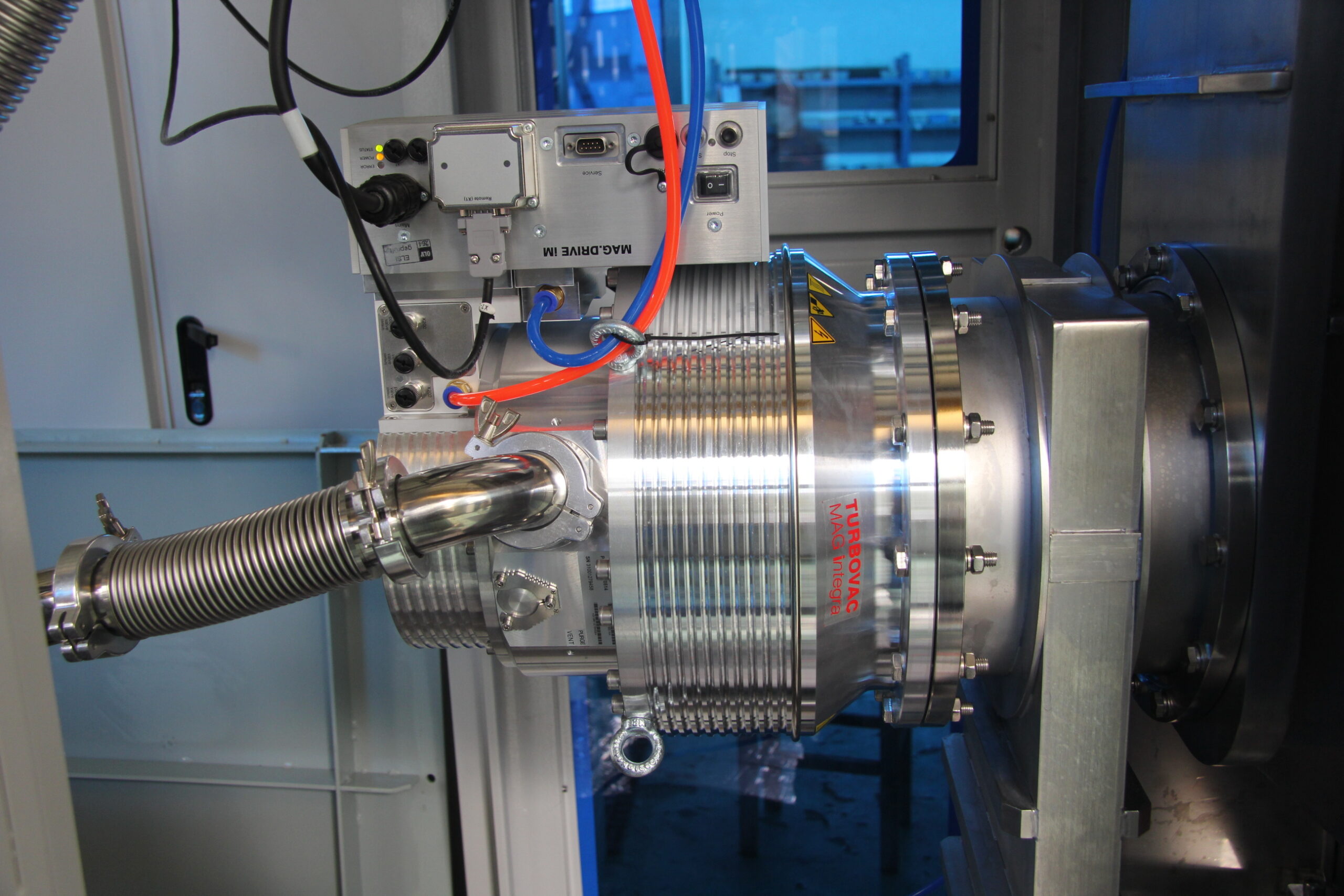

| 1 | Vacuum Pumping System : Turbo Molecular pump + Roots Pump+ Mechanical Pump + Holding Pump |

| 2 | Vacuum Measuring System: Pirani + Penning Gauges |

| 3 | Heating System: heaters for substrates heating up to improve the adhesion |

| 4 | Water/Compressed Air Distribution System: modular design and fabaricated |

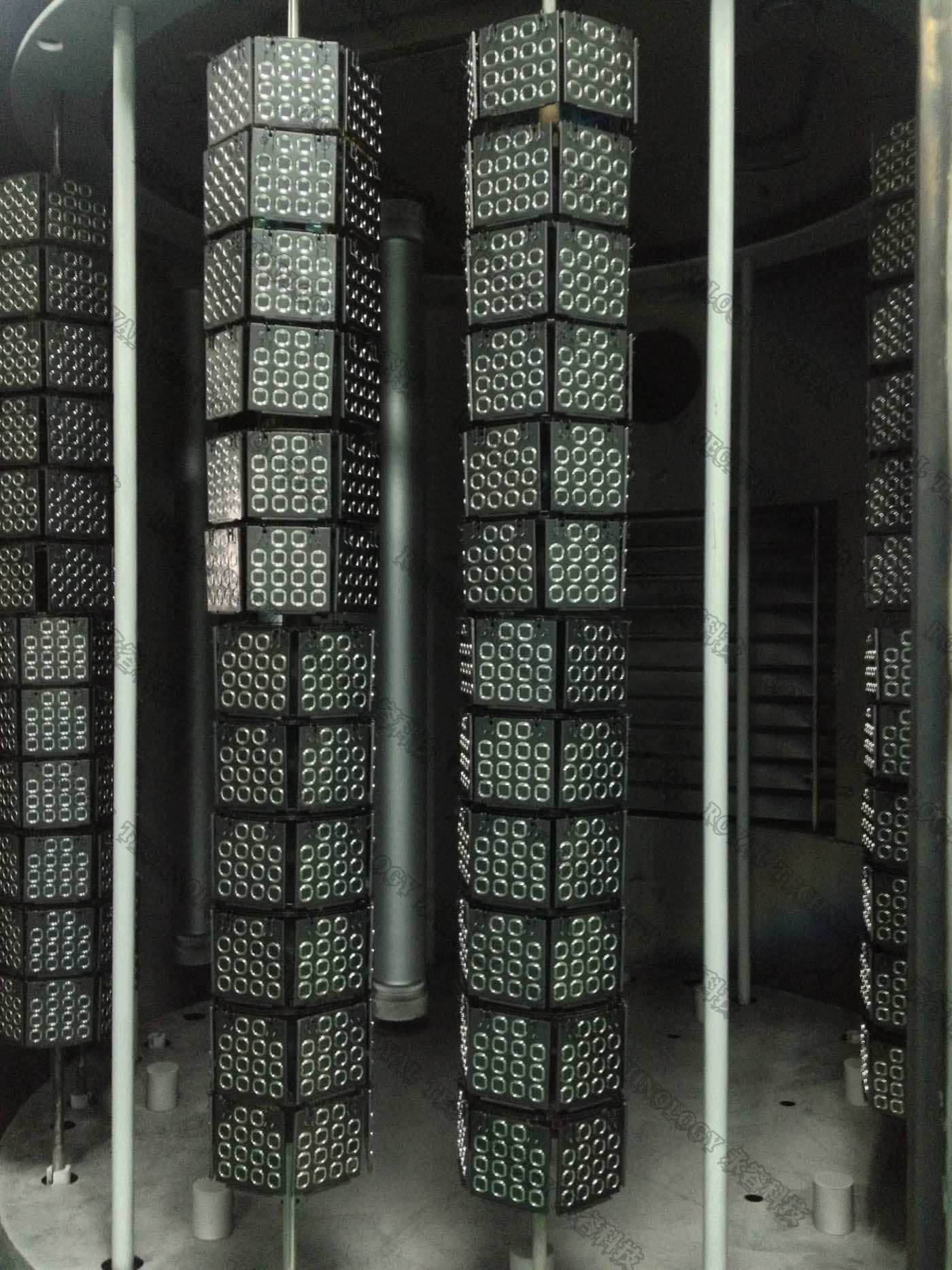

| 5 | Cylinder Sputtering Cathodes: 2/4/6/8 pairs of twins targets for option |

| 6 | Vacuum Gate Valve ( as option) |

| 7 | Electrical Enclosure (CE standard) |

| 8 | Vacuum Chamber (SS304/316L as requested) |

| 9 | Cathodic Arc Source (conventional arc cathodes ) |

| 10 | View Port ( 2 distributed on the door for inspection inside of deposition chamber ) |

| 11 | Processing Gas Distribution System ( Meter Flow Controller for 4 channels ) |

| 12 | Rack Driving System ( planetary driving model) |

| 13 | Carousel |

Technical Specifications: 2 models machine are introduced here mainly for massive production.

| Description | RTAS1250 | RTAS1612 |

| Deposition Chamber (mm) | φ1250 * H1250 | φ1600 * H1250 |

| Planetary Driving

Effective Coating Area (mm) |

8: φ270*H850

10: φ230*H850 |

10: φ300*H850

16: φ200*H850 |

| Circular Arc Cathode (sets) | 7 | 12 |

| Cylinder Sputtering Cathodes (pairs) | 3 /4 | 4 / 6 |

| Pulsed Bias Power

(KW) |

36 | 48 |

| DC / MF Sputtering Power (KW) | 36 | 4*36 |

| Arc Power (KW) | 7*5 | 12*5 |

| Vacuum Pumps | 2* Turbo Molecular Pumps

1*SV300B 1*WAU1001 1*TRP60 |

3* Turbo Molecular Pumps

2*SV300B 1*WAU2001 1*TRP90 |

| Max. Power Consumption (KW) | 200 | 245 |

| Average Power Consumption(KW) | <75 | <100 |

| Operation Space (L*W*H) mm | 4300*3700*2800 | 5000*4000*2800 |

Flexible configurations: the machine is set according to coating processes and customers’ requirements