Decorative PVD is often used for interior automotive finishes and the choice of this coating is not limited to the PVD decorative effect to improve the appearance. Its application also improves the solidity and lifetime of these parts, and consequently they have greater corrosion and oxidation resistance.

PVD is more ecological than many other finishing processes. It can be applied without the production of harmful chemical substances or hazardous waste.

In nowadays, in view of global technology industry, it’s quite important for all manufacturers to develop and find the best coating solutions to improve products quality and saving production cost, plus, have to take care of our environment.

Especially in vehicles industry, as an essential transportation tool of human being, it is an indispensable part of our daily life. So how to solve “energy shortage – petrol”

“ Petrol’s burning CO2 and hazard gas out, bring pollution to our planet” “ high production costs” issues. Thanks PVD coating technology, which has been solved these problems and improving this bad situation.

PVD technology has been widely used in various parts of vehicles manufacturing process, please review below image and learn what Royal Tec can provides you:

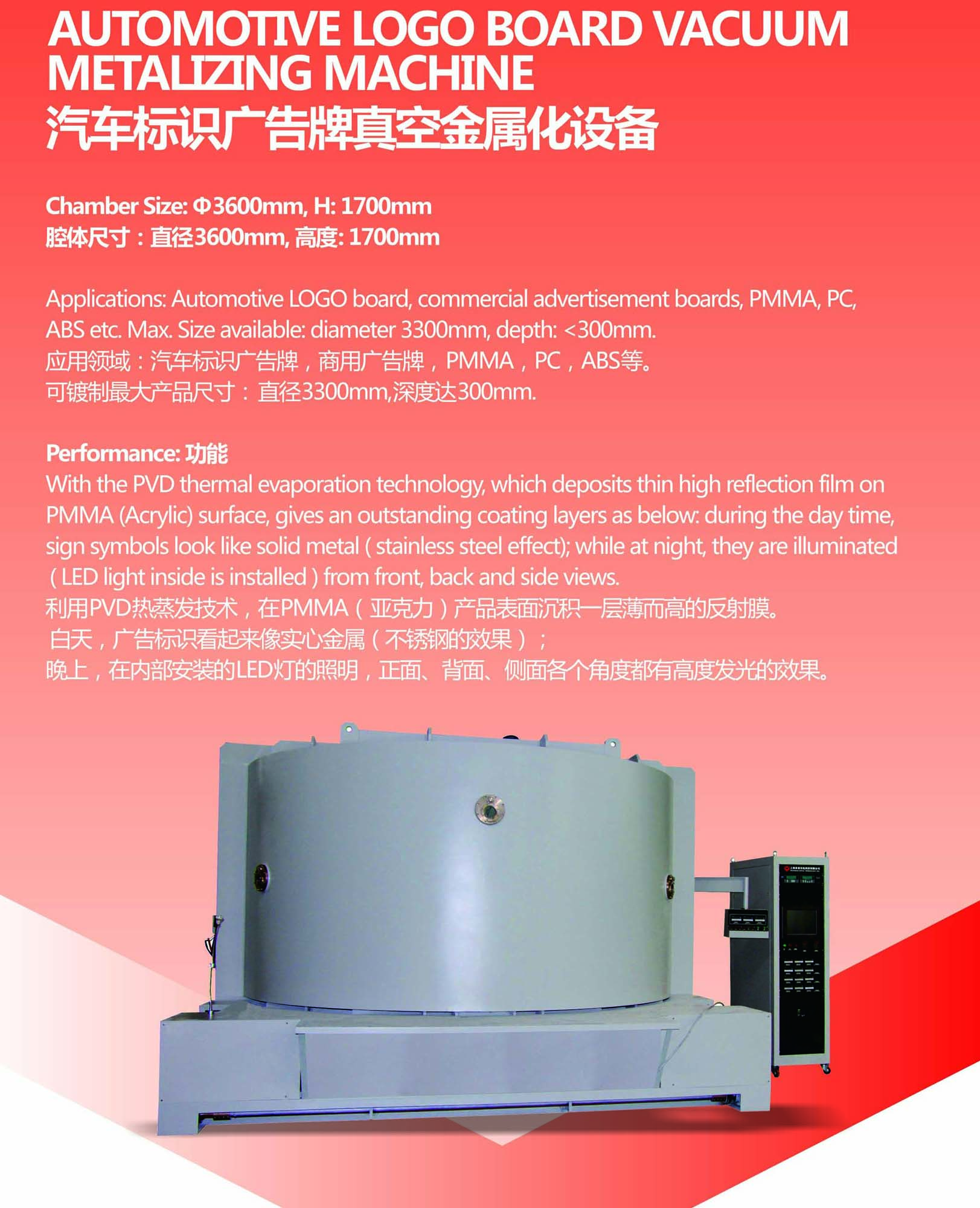

1. Vacuum Metalizing Equipment

A: Automotive Lighting Reflectors

B: Exterior & Interior Trims, handles

C: Automotive LOGO LED board

D: Bezels and bumpers

2. PVD Hard Chrome Sputtering System

A: Car Wheels

B: Car Mirrors

Royal Tec has developed S, M, L batch standardized models to satisfy our customer’s demand.

3. Hydrogen Fuel Cell Sputtering System

Disruptive innovative technology in the FCEV industry