16 – medical arc

PVD Coatings on Medical Instrument Industry Application

- Bio-compatible Medical PVD Coating

Experienced surface treatment and PVD coater for medical instruments, orthopedics, probes, alignment devices, implants and surgical cutting tools. Coatings are bio-compatible and acceptable for use with external and internal devices that come in contact with skin, tissue, bone and blood.

- Coating Properties

- Improved wear resistance

- Reduced friction

- Bio-compatibility

- Decorative colors & aesthetic

- Chemical barrier

- Nickel Sensitivity

- Saline Solutions

- Sterilization

- Bio-compatible Coating Films

TiN and ZrN family of gold thin coatings for specialized medical devices and instruments.

TiAlN, AlTiN, AlTiSiN, CrN, TiCN, ALCrN family of medical coatings for cutting tools and specialized applications.

DLC coatings on the medical equipment for a very low co-efficiant of friction.

( a-C:H DLC):

| # | Coating Film | Color | Hardness HV | Coefficient of Friction | Bio-compatibility Testing |

| 1 | TiN | Gold | 2300-2500 | 0.35 | Pass |

| 2 | CrN | Silver | 2000-2200 | 0.35 | Pass |

| 3 | TiN/TiCN | Bronze/Gray | 2800-3200 | 0.3 | Pass |

| 4 | AlTiN | Violet/Black | 3000-3400 | 0.35 | Pass |

| 5 | TiAlN | Copper/Bronze | 3000-3200 | 0.4 | Pass |

| 6 | ZrN | Pale Gold | 2300-2500 | 0.35 | Pass |

| 7 | DLC (a-C:H) | Black | 2000-3000 | 0.1 | Pass |

| 8 | AlTiCN | Black | 1200-1800 | 0.2 | Pass |

| 9 | AlTiN | Black | 1200-2000 | 0.2 |

- Note:

The data generated from laboratory samples. Coating films properties may vary depending on customer’s material, surface condition ( high polished or others) and products 3D geometry.

TiN coating

Titanium nitride (TiN) coating is clinically being used on orthopedic implants for hip, knee, shoulder and ankle replacements as well as dental implants, brain and ear implants etc. Bio-compatibility: non-toxic.

Advantages

- Improved instrument performance

- Create distinct color identification, improve your product competition from others.

- Decrease friction and improve wear resistance: for example 0.35 VS 0.7 for un-coated steel.

- Oxidation and Corrosion Resistance

- Barrier layer for various solutions and environmental exposures.

PVD Coating Machine Models

1) Arc Cathode Plating

2) Magnetron Sputtering Coating

3) Arc + Sputtering Coating.

4)Royal Technology recommends our standard machine: RTAC (RTAS)1000

***Both machine equips with linear ion source for surface etching and PAPVD (Plasma Assisted Deposition ) ***

Others

1) Customer provide the products sizes, material, surface treatment before PVD coating; and productivity for a equipment size recommendation.

2) Samples coating required by customer can be satisfied.

3) Customers are very welcomed to inspect our company and have a visiting in our customer’s site to learn the whole coating process.

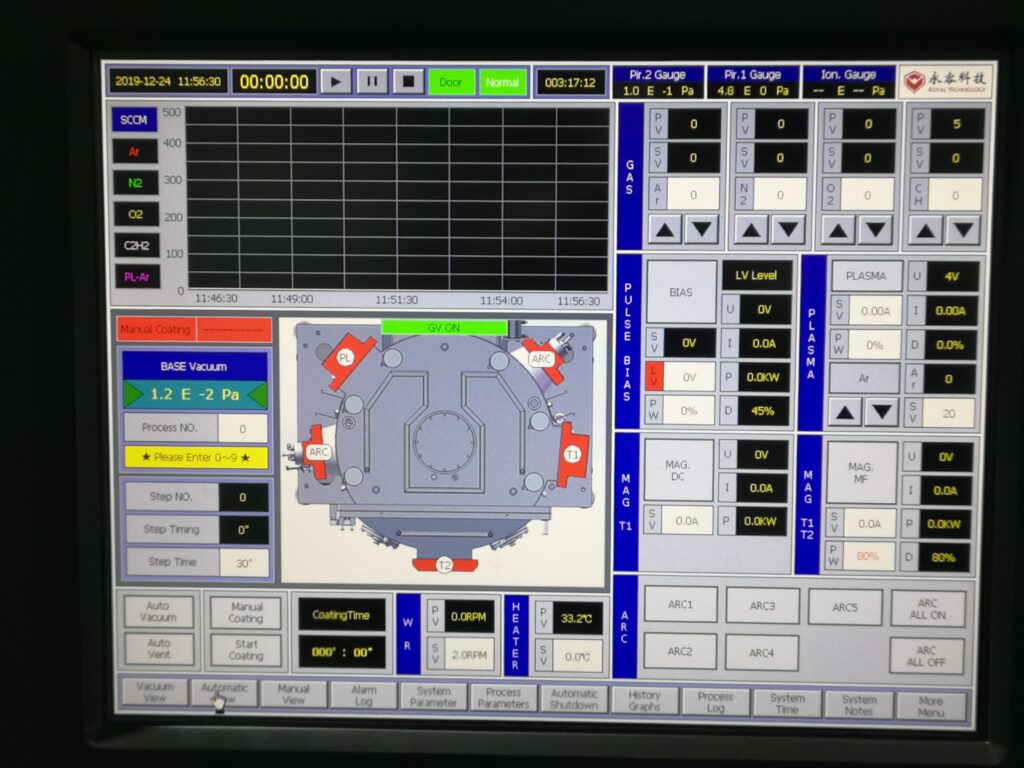

Medical Instruments Functional Coating Machine

The medical instruments functional coating machine is perfect combination of arc and sputtering cathodes, plus the linear ion source device is available for plastic material parts surface etching before deposiiton.

Benefits: eco-environment, easy to operate, compact foot print, low cost of owner ship, fast substrate exchange.

Coating Colors: gold, black, brown, grey, Chrome colors etc. Gold Colors: TiN, ZrN, TiN+Au, ZrN+Au

Rose Gold Colors: TiCN, TiAlN, TiCN+Au-Cu, TiAlN+Au, Cu

Chrome colors: CrN, Ti, Cr

Gray Colors: stainless steel, stainless steel (N)

Brown Colors TiCN, TiAlCN, ZrC

Blue Color: TiO, CrO, TiALN

Black Colors: TiC, TiC+iC, TiCN, TiAlN, TiAlCN

Coatings Advantages: high shiny and bright colors, strong adhesion & excellent scratch protection, fast deposition rate, good diffraction etc.

Key completed system listed below:

A.Vacuum Chamber

B.Vacuum Pumping System

Roughing Vacuum Pumping System ( Mechanical Pump + Roots Pump)

High Vacuum Pumping System (Diffusion Pump or Turbo Molecular Pump)

Holding Pump

C.Vacuum Measuring and Control System

D.Rotational Rack System

E. Deposition System

F.Electrical Control and Operation System

G.Water Cooling and Gas Distribution System

H.Sub-system

| Model | RTAS1000 |

| Effective Chamber Size | Φ1000 x H1000mm |

| Deposition Sources | Cylinder Arc Sources+ Sputtering Cathodes( Planar/Cylinder Sputters for option) +Linear Ion Source |

| Vacuum Pumping System ( Leybold Pumps + Turbo Molecular Pump)

|

SV300B *1 set (300m³/hr) |

| WAU501-1set

(1000m³/hr) |

|

| TRP48*1 set (48m³/hr) | |

| Turbo Molecular Pumps:

1 set (3500L/S) |

|

| Sputtering Power Supply | 1*24KW |

| Arc Power Supply | 6*5KW |

| Bias Power Supply | 1*24KW |

| Planetary Rods | 6/8 planetary axis for selection |

| Ultimate Vacuum | 9.0*10-4Pa (empty, clean,room temperature) |

| Working Power Requirement | 3Phase 5 lines

AC380V,50HZ,55KW |

| Cooling Water | Recycle cooling water, industrial water chiller + EDI purified water device |

| Processing Gas (99.99%) | 4 ways |

| Footprint (mm) | 2000*2000*2500 |

| Total Weight(KGS) | 4500 |

| Total Power Consumption(Approx.) | 50KW |

| Actual Power Consumption(Approx.) | 30KW |

Machine Operation HMI Pages – Auto Coating Process

Model: RTAS1000

Location: China

Time: 2019