Antibacterial Coatings and Coating Equipment

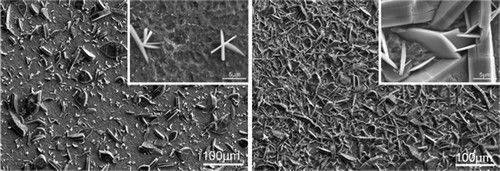

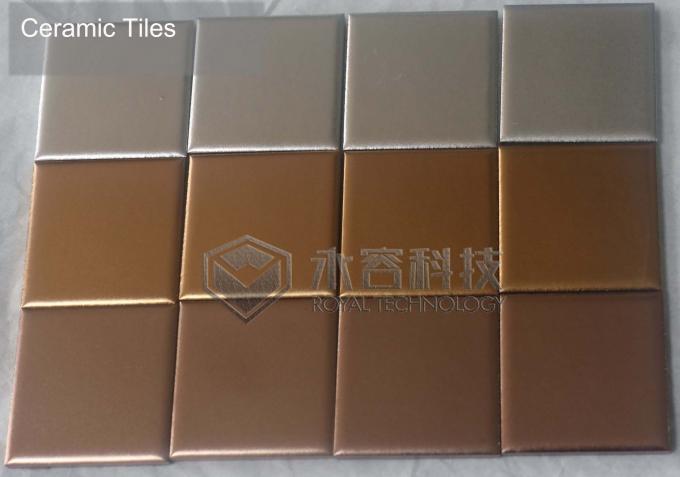

The demand for antibacterial coatings on frequently touched surfaces has long existed. With the rising public health and domestic hygiene awareness, decorative coatings on SS and ceramic products, such as taps, door handles, hand rails, tiles,faucets, bathroom fittings with antibacterial properties may attract more attention from consumers than ever.

Royal Technology developed the antibacterial functional coating without making the process too complicated and also can retain other PVD properties:

– Green coating technology

– Low production cost

– High antibacterial effectiveness and long lasting

– Scratch resistance

– Corrosion & wear resistance

We are ready to share this advanced technique with our customers, anyone who is interested in providing the antibacterial finishing as a high added-value on your products, please contact us for a FREE consultation.

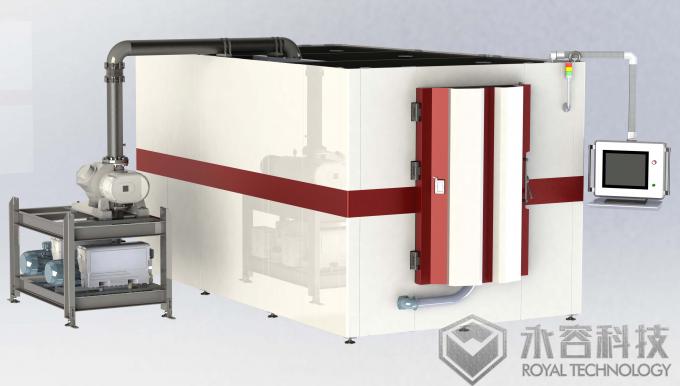

Antibacterial Coating Machine: RT1400-AntiBac