Plug-in Designed PVD Magnetron Sputtering Machine Installation by Customer with our Online Supervision

Due to the epidemic outbreak becoming a global problem, our Engineer is unable to go to Poland to provide the installation service. On March 6, 2020, we decided to supervise customer online and assist

them to finish the assemble, testing, commissioning steps.

From 1PM till 5PM, we guided the customer with our engineer’s online instructions & supervision, after the machine started working and made 2 cycles testing.

A very happy and successful cooperation, great thanks to Mr. Pawel and Michael’s excellent work, thanks for your complete support and understanding.

Industrial Water Chiller- preparing cooling water connected with PVD machine

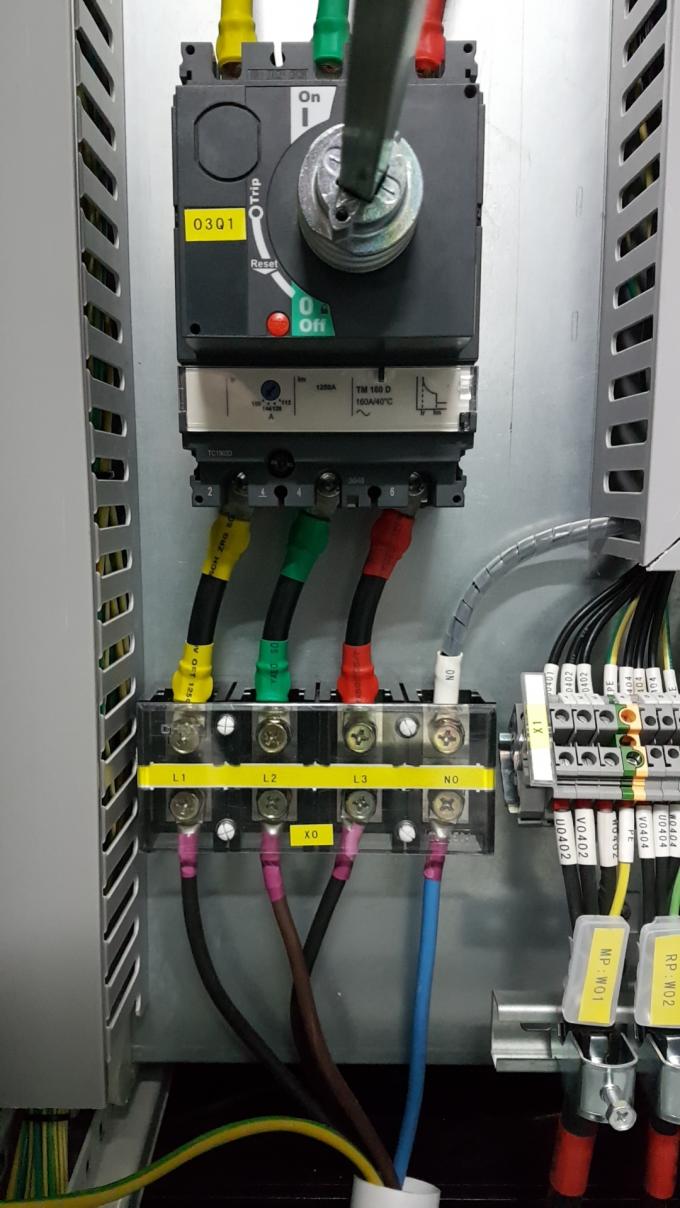

Three phase four wires connection, ABCN and PE wire (ground line, ZERO)

Working/reactive gas. compressed air preparation

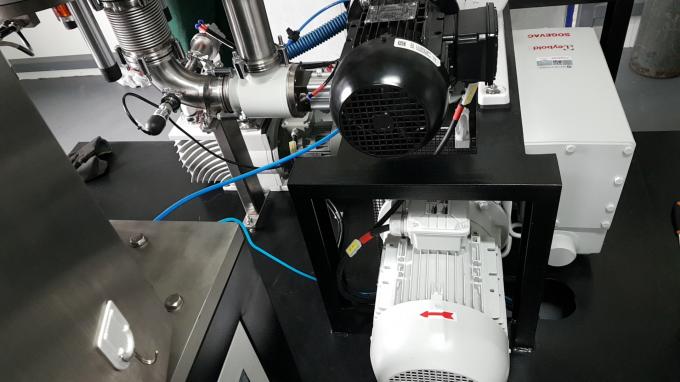

All motors of pumps rotation direction inspection

Chamber Cleaning/inspection before loading

Automotive wheel/Hub’s Loading

PVD magnetron sputtering deposition process

PVD finishing: