CsI High Vacuum Deposition System is exclusively designed for CsI metalization on scintillation screens in an extremely high vacuum environment. The CsI scintillators with 200~600µm thickness range, high uniformity of thickness and brightness performance:

Ultra- High Spatial Resolution of Imaging;

Fast response for sharper imaging;

Class leading edge-to-edge image areas;

Optical absorb layers or reflector layers;

Low patient X-ray dose.

Substrates Applied: TFT glass, Fiber Optic Plate, Amorphous-carbon plate, Aluminum plate

Application: for security check and inspection, high energy physics education, nuclear radiation detection and medical imaging: chest examination, mamography, dental – oral and panoramic.

The model CsI950A+ is updated based on the 1st generation CsI950, its advantages:

1. Efficiency

-CsI-950A+ model comes with 2-rotary rack – structure based on Generation – one CsI-950 model.

-Double-capacity for max. size substrate: 500 x400mm.

2. Repeatability & Reproducibility

-Through high precision parameter control system,

-Automated process control software and program,

-User friendly operation.

3. Reliability

-24/7 days non-stop operation;

-Inficon Film Thickness Controller to monitor the film thickness inline.

-Temperature control accuracy: ±1 ℃, multi-stage setting, automatic temperature data recording and control

-Rotary racks equipped with Servo-Motor for high accuracy and stability.

4. Safety

-High vacuum pump: Magnetic Suspension Molecular Pump, with nitrogen gas blowing device to avoid hazardous material evaporation to the air;

-All electrodes are equipped with safety protection sleeves.

Technical Parameters

| Description | CsI-950 |

CsI-950A+

|

| Deposition chamber (mm)

|

φ950 x H1350 | φ950 x H1350

|

| Loading rotary racks | 1 | 2 |

| Evaporation sources | 2 | 2

|

| Heating method | Iodine tungsten lamp

Max. 1800℃ |

Iodine tungsten lamp

Max. 1800℃ |

| Ultimated vacuum pressure (Pa) | 8.0×10-5Pa | 8.0×10-5Pa |

| Magnetic Suspension Molecular Pump | 1 x 3400L/S | 1 x 3400L/S

|

| Roots Pump | 1 x 490m³/h | 1 x 490m³/h

|

| Rotary Vane Pump | 1 x 300m³/h | 1 x 300m³/h

|

| Deposition Controller | Quartz Control x 1 | Quartz Control x 1

|

| Power Consumption (KW) | Max. approx. 62

Average approx. 32 |

Max. approx. 65

Average approx. 35 |

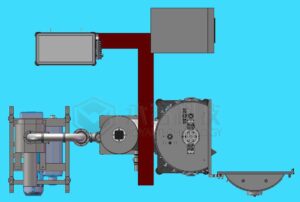

Layout

Built Time: 2014, totally 4 sets

3 sets CsI950 and 1 set CsI950+

Location: Jiangsu, China